MAIN APPLICATIONS:

- Transfer, booster and Process pumping for general industry needs

- Unloading of tank lorries and rail car

- Loading of rail cars, tank lorries and barrel filling

LIQUIDS:

- All grade of fuel oils, Lube oil, Paints, Varnish, Resins, Grease and similar high/low viscous products having some lubricating value

PRODUCT SPECIFICATIONS AND FEATURES:

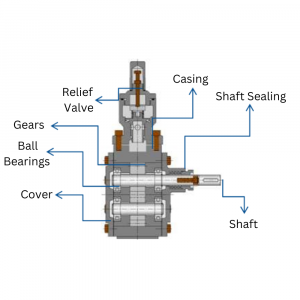

| Casing | Cast Iron |

| Cover | Cast Iron |

| Gears | Carbon Steel – Nitrided |

| Shaft | SS 410 |

| Seal | Non Asbestos Gland Pack / Mechanical Seal |

| Capacity | 125 – 850 lpm |

| Outlet Pressure | Up to 10 bar |

| Viscosity | 6 – 5000 cst |

| Temperature | Up to 140°C |

| Speed | Up to 1450 rpm |

| Drive | Direct Only |

| Rotation | Anti-clockwise facing pump drive shaft |

VALUE PROPOSITION:

- High speed

- No overhung bearing loads

- Protected by a relief valve

- Relatively quiet operation

- Single sealing, external bearing

- Low noise and pulsation

- Reversibility

- Easy maintenance

MARKET SEGMENTS:

- Power Generation

- Steel

- Paint

- Chemical

- Oil Depots

CONSTRUCTION:

Each gear is supported by shaft with bearings on both the sides of the gear. Because the gears are supported on both the sides, external gear pumps are quiet – running and are routinely used for low and medium applications. With no overhung bearing loads, the rotor shaft can not deflect and cause premature wear. Comes with a Built-in Relief valve

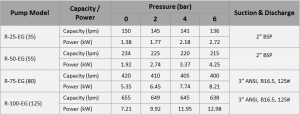

PERFORMANCE DATA:

Testing Medium: Lube Oil Viscosity: 75 cSt Speed: 1450

Reviews

There are no reviews yet.