MAIN APPLICATIONS:

- Loading, unloading, transfer, circulation and process pumping of a very wide range of products typically as thin as diesel oil to extremely high viscous substances.

- Unloading of tank lorries and rail car.

- Loading of rail cars, tank lorries and barrel filling.

LIQUIDS:

- Bitumen, coal, tar, crude oil, fuel oil, lacquer, linseed oil, lubricating oils, molasses, paint,

PRODUCT SPECIFICATIONS AND FEATURES:

| Rotors | Carbon Steel |

| Casing | Cast Iron |

| Pinion | Carbon Steel |

| Shaft | SS 410 |

| Seal | Non Asbestors Gland Pack / Mechanical Seal |

| Capacity | 70 – 800 lpm |

| Outlet Pressure | Up to 7 bar |

| Viscosity | 40 – 1,00,000 cSt |

| Temperature | Up to 200°C |

| Speed | Up to 1450 rpm |

| Drive | Direct Only |

| Rotation | Anti-clockwise Facing Pump Drive Shaft |

VALUE PROPOSITION:

- Smooth quite flow

- Excellent Self Priming

- Insensitive to viscosities

- Single sealing, external bearing

- Low noise and pulsation

- Reversibility

- Easy maintenance

MARKET SEGMENTS:

- Food & Beverages

- Pharmaceutical

- Chemical

CONSTRUCTION:

Single shaft design well supported on outboard bearing enables to pump products even with poor lubricating value. The main gear is keyed to the drive shaft and rotates concentric in the pump casing. Idler is located on an eccentric pin on the front cover to rotate freely and meshes with main gear when assembled. A crescent shaped partition precision machined on the front cover, maintains a small but positive clearance to achieve perfect sealing between parts.

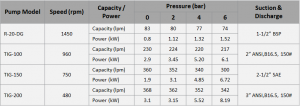

PERFORMANCE DATA:

Testing Medium: Lube Oil Viscosity: 75 cSt Speed: 1450

Reviews

There are no reviews yet.