MAIN APPLICATIONS:

- Transfer of lubricating oils.

- Pressure lubrication and cooling of bearings.

- Oil circulation through cooler, gear lubrications.

- Transfer of fuel oils.

- Boosting of fuel oil pressure for oil burner service and fuel injection pumps.

LIQUIDS:

- Pump has been designed to handle fuel and lubricating oil as well as other fluids with similar properties.

PRODUCT SPECIFICATIONS AND FEATURES:

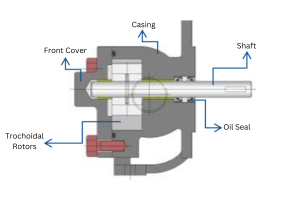

| Rotors | Sintered Iron, Cast Iron |

| Casing | Cast Iron |

| Shaft | SS 410 |

| Seal | Oil Seal (Nitrile) / Gland / Mechanical Seal |

| Capacity Outlet | 03 – 200 lpm |

| Pressure | Up to 8 bar |

| Viscosity | 6 – 1500 cSt |

| Temperature | Up to 80°C |

| Speed | Up to 1450 rpm |

| Drive | Direct Only |

| Rotation | Anti-clockwise facing pump drive shaft |

VALUE PROPOSITION:

- High speed operation and vibration free running

- Smooth, pulsation free flow

- Negligible maintenance

- High suction lifts and low noise level

- High volumetric efficiency and overall efficiency

- Compact and light weight design

MARKET SEGMENTS:

- Power Generation

- Oil & Gas

- Machine Tool

- Steel

CONSTRUCTION:

There are only two pumping elements in a Rotary Trochoidal pump. The flow of liquid is axial through elements. Also there is only one shaft, well supported at both ends of rotor for smooth, vibration-free running and eliminating bearing problems normally found in conventional gear pumps. The pumps has a very low noise level.

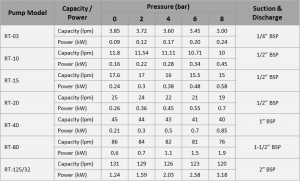

PERFORMANCE DATA:

Testing Medium: Lube Oil Viscosity: 75 cSt Speed: 1450

Reviews

There are no reviews yet.