| Maximum Performance Data | |

|---|---|

| Capacity | Diff. Pressure |

| upto 2700 lpm | upto 24 bar |

| Operating Parameters | |

| Viscosity | From 1 to 1,00,000 cSt |

| Fluid Temperature | upto 120 C |

| Material of Construction | |

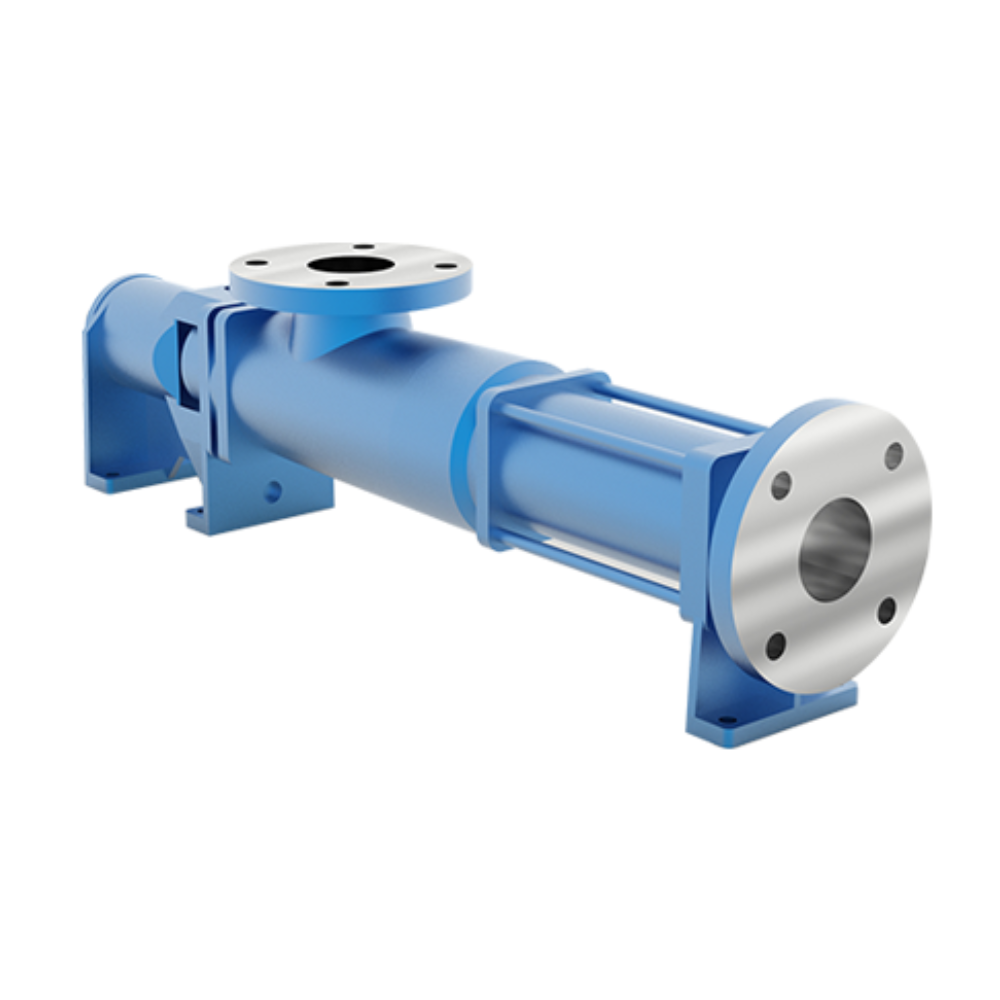

| Casing Options | Cast Iron / Stainless Steel / Fabricated Steel / Fabricated Stainless Steel |

| Rotor Option | Stainless Steel / Tool Steel |

| Stator Options | Nitrile / EPDM / Viton / Hypalon |

| Sealing Options | Gland Packing / Mechanical Seal |

| Construction Features | |

| Stages | one / two |

| Stator Construction | Standard / Equal Walled |

| Mounting Options | Horizontal Foot / Vertical tank / Gear Box |

Reviews

There are no reviews yet.